WarehouseTWO – Company Reshoring Case Study

Founded in 2006 and acquired by Rubber Tree in 2021, WarehouseTWO has grown into a reputable and reliable business helping a wide range of distributors solve their inventory availability problems. For over 15 years the company has been at the forefront of inventory sharing.

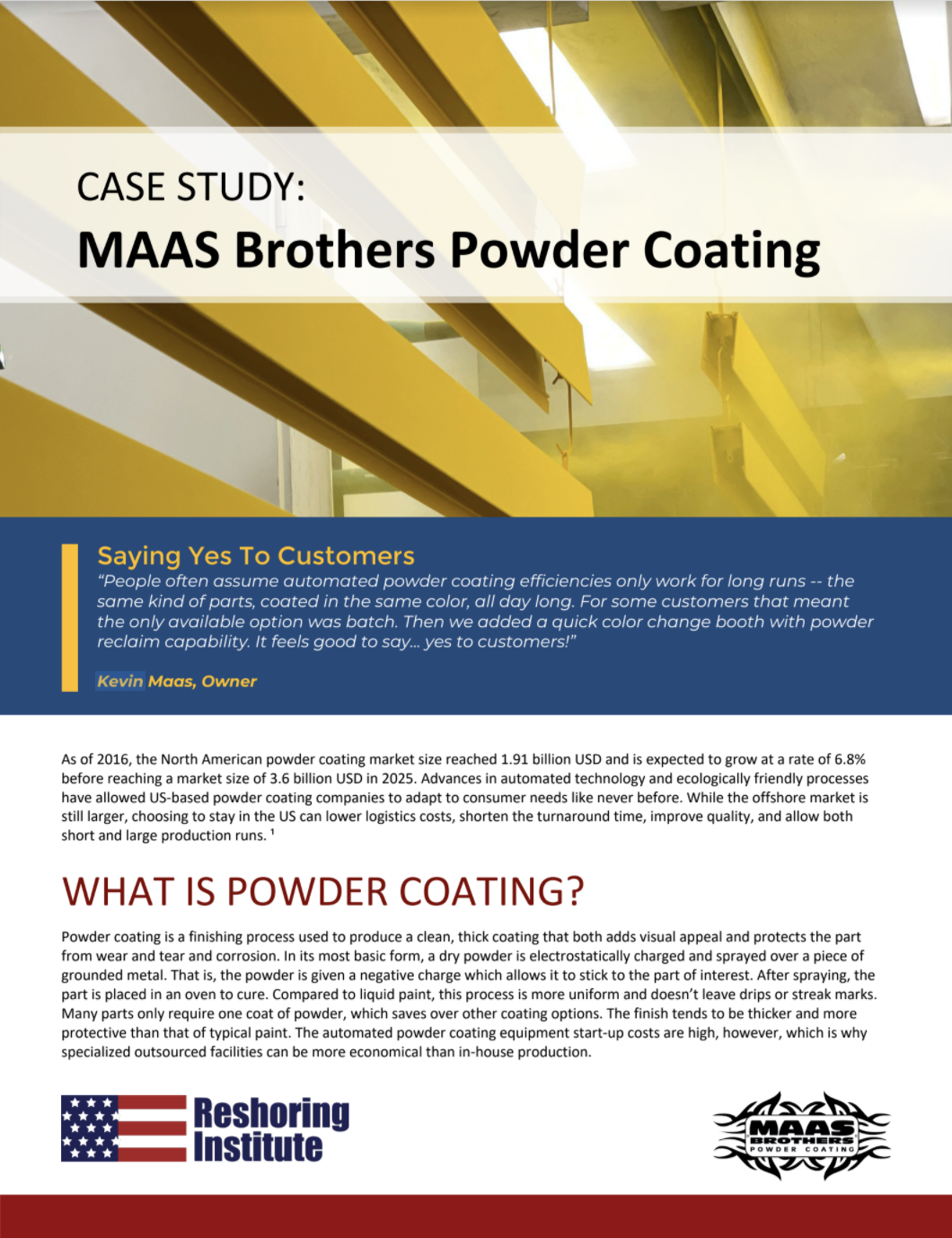

MAAS Brothers Powder Coating – Company Reshoring Case Study

Maas Brothers has been dedicated to problem-solving and process improvement since Kevin and Kraig Maas founded the company in 1998 in Livermore, California. Customers are always invited to stop by, meet the founders, and take a tour of the facilities.

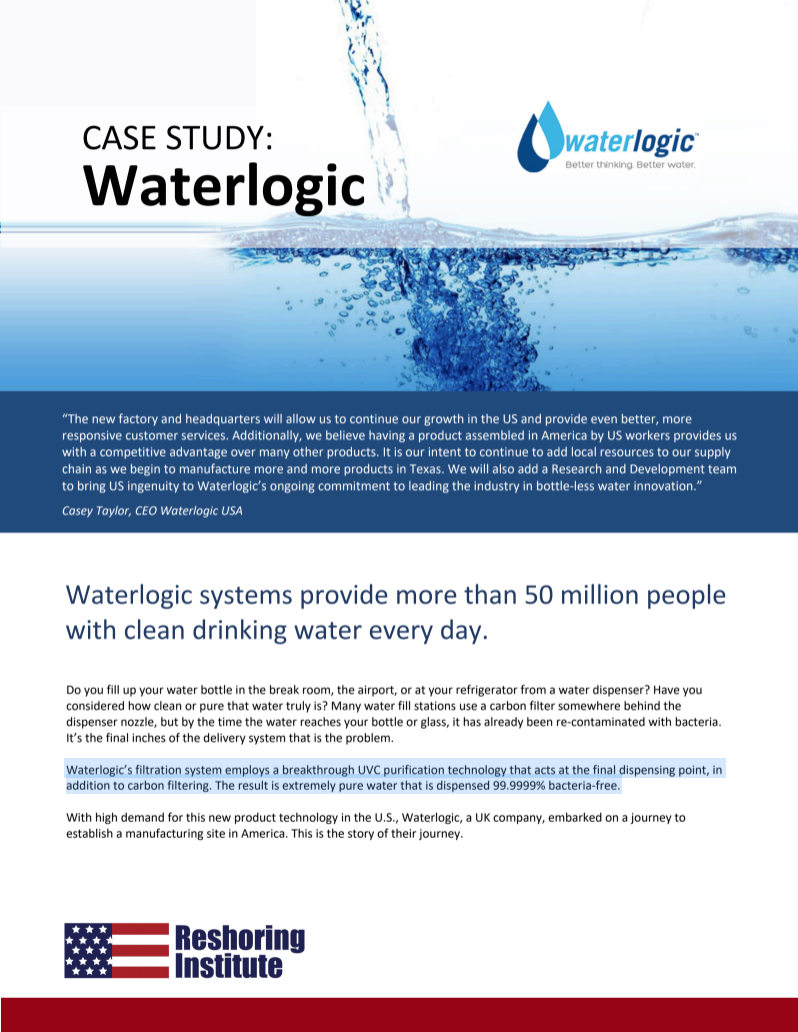

Waterlogic – Company Reshoring Case Study

Waterlogic systems provide more than 50 million people with clean drinking water every day. Waterlogic’s filtration system employs a breakthrough UVC purification technology that acts at the final dispensing point, in addition to carbon filtering. The result is extremely pure water that is dispensed 99.9999% bacteria-free.

Vikki Vi – Company Reshoring Case Study

For many years, apparel and textile manufacturing was mostly located to Asia, Mexico and South America where labor costs were low. But that is no longer the case. With the popularization of fast fashion and customers’ constant demand for new and better items in a fraction of the time, companies are now considering reshoring.

Big Ass Fans – Company Reshoring Case Study

During the Recession of 2008, approximately 8.8 million jobs were lost throughout the United States. Mass layoffs were sweeping across the nation. But for Big Ass Fans, a fan, lighting, and controls manufacturing company headquartered in Lexington, Kentucky, this was not the case.

Crayola – Company Reshoring Case Study

Crayola is a U.S. based company that has remained true to its roots throughout its growth history. Crayola’s domestic manufacturing is impressive, with over three billion crayons rolling off of the Easton, PA production line yearly. 83% of Crayola’s customers are in North America, and over two thirds of all products which are sold globally are made in the United States.

View Case Study | Download PDF

GE – Company Reshoring Case Study

GE’s reshoring efforts brought thousands of jobs back to Louisville, Kentucky, the refurbished facility is recognized as a Center for Excellence and the products are innovative and energy efficient.

View Case Study | Download PDF

Evolve Manufacturing Technologies – Company Reshoring Case Study

Contract manufacturers like Evolve provide a viable alternative to offshoring. Smaller CMs provide high quality, customer-focused service at a reasonable price. Evolve helps its customers model the Total Cost of Ownership (TCO) when making an offshore or restore decision.

IRT – Company Reshoring Case Study

In 2013, iRT announced its commitment to bring manufacturing jobs back to the United States. Since the announcement of its Reshoring initiative, more than 80% of iRT’s components for its road, cyclocross, and mountain bike wheels are sourced from U.S. companies. To aid its Reshoring efforts, iRT invested in 3D printing for wheel hubs, which saved the company $100,000 over a two-year period, enabling it to compete in the competitive bicycle racing industry.

View Case Study | Download PDF

Maxim – Company Reshoring Case Study

Close your eyes for a moment and imagine a symphony orchestra. The famous conductor taps his baton, and the violins begin to play. Then the cellos and woodwinds join. The percussion adds tempo and depth to the sound and the trumpets brighten the mood. Together the sound is magnificent. Now imagine a factory floor full of machines that each have a different function and pace. When in sync, production flows efficiently…

Mel Gambert Custom Shirtmaker – Case Study

Gambert Shirts has been operating in the US for 85 years and has experienced a significant amount of change. In 1965, 95% of the clothing sold in the USA was made in the USA. Today, that number is 4-5%. So how has Gambert survived?

RK Logistics Group– Silicon Valley Foreign

Trade Zones

At times, supply chain professionals are expediting everything from the smallest parts to finished products in order to meet market demand. Other times, supply chains need to be slowed in response to the same market forces. The speed needed in global supply chains varies as business requirements and supply chain strategies shift and change in response to supply and demand.

Rethink Robotics– Company Reshoring Case Study

Baxter is differentiated from its competitors by being a “co-bot”. “Co-bots are designed to work alongside humans with quick programming for simple, repetitive manufacturing tasks. Baxter is designed to perform “human class and human scale tasks in a human environment”. This positioning allows Rethink to avoid direct competition with industrial robots on the market. Instead of replacing those bots, Baxter can complement and work side-by-side with them.

Starbucks – Company Reshoring Case Study

Starbucks started their reshoring efforts by reopening a ceramics factory in Ohio and then a month later they announced a new facility in Georgia. This case study explores the decision factors and results of reshoring.

View Case Study | Download PDF

Todd Shelton – Company Reshoring Case Study

Todd Shelton is one of the first apparel companies to reshore their manufacturing from Asia to New Jersey. This case study explores the reasons why, the process to reshore and the results they have seen.