Published Books & Articles

Why did my Amazon order arrive in a giant box?

Managing shipping operations often requires trade-offs, and right-sized packaging is easy to dismiss

Have you ever opened an e-commerce package that is filled with packing materials for one small item? The box is 5 or 6 times bigger than the item and filled with paper wadding or bubble wrap. Did you wonder why the shipper used such a large box?

Most shipping operations use standard-size boxes—small-medium-large—and if the product doesn’t fit the box, packing materials such as paper wadding, bubble wrap, or Styrofoam peanuts are added. This is not the most efficient way, nor the most sustainable way to ship products. The receiving customer is left with an oversized box and a mound of packing materials which may end up in a landfill.

This Supply Chain Year Will Be Dependent on Politics

Governmental policies and regulations have become an integrated part of supply chain life

Like so many organizations, the Reshoring Institute did a predictions survey for 2024. The results surprised us.

Out of all the responses, politics was the most often cited regarding what will affect supply chains in 2024. Fifteen or 20 years ago, politics wouldn’t have garnered even a mention, as government and laws provided mere background and context for doing supply chain work. But today, politics are on everyone’s mind and are expected to influence the majority of supply chain decisions this year.

Foxconn’s Tijuana Manufacturing Operation Shows the Nearshoring Possibilities

The facility is a testament to investment in Mexico as part of the nearshoring trend

Over the past 20 years, many companies, particularly in electronics, have outsourced manufacturing. One of the giants of contract manufacturing is Foxconn, the famous CM making Apple products in China. In addition to China, Foxconn has established manufacturing facilities in many countries, including Mexico.

The reshoring/nearshoring movement has companies considering Mexico as a viable low-cost alternative to China. The minimum wage in Tijuana as of January 2024 is approximately $2.25/hour. Land, facilities, and the overall cost of operations are lower, too.

The Astonishing Port of Laredo

Laredo is the largest U.S. land port. More than 14,000 trucks per day cross the border at Laredo.

I visited Laredo in October to see for myself. Jacob, one of our interns from the Reshoring Institute, came with me to assist with our research on cross-border commerce and the massive shift to nearshoring manufacturing. What we discovered was jaw-dropping volumes, advanced technology, community college education in trade compliance, and a welcoming business environment.

Will an Investment ‘Supercycle’ Spark the Revival of American Manufacturing?

Will three big recent funding measures entice manufacturers to shift production from China back to the U.S.?

The trend has been evident for a few years now: manufacturers reducing production in China, in favor of lower-cost countries and, possibly, the U.S. Three big investment initiatives — the Inflation Reduction Act, CHIPS and Science Act and infrastructure funding bill — could be instrumental in triggering a rush of reshoring.

A Manufacturing Supercycle Has Begun

“We believe the U.S. is in the early stages of a manufacturing supercycle,” wrote Joseph P. Quinlan, head of CIO market strategy at Merrill and Bank of America Private Bank.

Photo by Susan Q Yin on Unsplash

Hidden risks in global supply chains

Do you think you already have enough to worry about with the obvious and known risks and have no time to address hidden risks? Rethink that approach. The risk of doing nothing could be disastrous to your business.

The Hidden Risk of Chinese Suppliers

Whether a company stays or goes, being alert for signs of supplier bankruptcy is essential for supply chain managers

The economic news coming from China isn’t good. While the U.S. economy is expanding, the Chinese economic growth rate has declined from double digits just a few years ago to 3% in 2022.

The Last Word with Rosemary Coates

Reshoring is no longer just an idea. Real job growth in the US indicates the trend is upward and sustainable. A recent survey by Kearney Consulting reported that 96% of responding CEOs are considering reshoring their operations or have already done so.

Read More >

Reshoring the Food Supply Chain

Global supply chains are headline news. Shortages and disruptions over the past few years have caused companies in all industries to reconsider where they are sourcing and processing products and the potential for reshoring their supply chains.

Read More >

DC Velocity – April 3, 2023 – Interview – April 3, 2023

Coming home: interview with Rosemary Coates – In a bid to shorten their supply chains, companies are looking to bring manufacturing back to U.S. shores. But are we ready? Rosemary Coates answers that question and more in the last of three interviews on workforce issues.

Read More >

Finding and managing “forever chemicals” in your supply chains

It’s time for supply chain folks to raise a red flag for possible worst case scenarios.

Polyfluoroalkyl substances (PFAS) are a large family of chemicals in use since the 1950s, to make a wide variety of stain-resistant, water-resistant and non-stick consumer products. They are in waterproof cosmetics, raincoats, Teflon pans, water-resistant hiking boots and fire-fighting foams to name a few products. They are in the products in your supply chain.

First, Biden talked about global supply chains

Then he talked about Made in America and transportation infrastructure in his State of the Union. That’s when I tuned in fully.

I usually half-listen to the State of the Union Address while I am doing something else at home. That was my plan this year, too. But then, I heard President Biden talking about global supply chains and I sat down in front of the TV.

Photo by Markus Spiske on Unsplash

Supply Chain Resolutions: Can we stick with it this year?

Here are six areas that could use some extra attention.

I just got home from my Zumba class at the gym. The studio was crowded with newbies and their personal New Year’s resolutions. From experience, I know that this will only last about 6 weeks and then we will get back to normal crowds with those of us who are die-hard gym goers. The rest of the people lose their will to stick with it.

So what resolutions and new ideas are ahead for supply chain management? Will we start new projects and commit to making improvements? Can we stick with it through the year?

Supply chain risk, not economics, now driving reshoring interest

FIRESIDE CHAT TOPIC: Reshoring as the next major strategic initiative.

DETAILS: A discussion with Rosemary Coates, executive director and chairman at the Reshoring Institute, about how companies are looking to navigate supply chain risks through reshoring.

Keynote: The New Reshoring Revolution in the U.S. Economy

Rosemary Coates, Founder and Executive Director at Reshoring Institute, is joined by FreightWaves Editorial Director, Rachel Premack, in this keynote address on day 3 of F3.

Photo by Christian Wiediger on Unsplash

What does the CHIPS and Science Act mean for global supply chains?

Semiconductors or “chips” as they are often called, are essential to our lives. They are in our cell phones, our cars, our laptops, our washing machines, our TVs and airline avionics – it’s hard to imagine a world without them.

Photo by CHUTTERSNAP on Unsplash

Supply Chain Woes Accelerate Reshoring, Nearshoring Trend

The impact of the COVID-19 pandemic followed by supply chain disruptions around the world has sparked a resurgence of companies bringing sourcing and manufacturing back to the United States or closer to U.S. shores.

Global Risk Mitigation: Using risk assessment tools to evaluate global suppliers

Now that the worst of it seems to be over, it’s time to take action to mitigate any future risk of supply chain disruptions. Developing a tool or using an existing software tool for assessing risk will help identify the weak links in your supply chain—but a tool alone is not enough.

Risk management has been among the top priorities on board agendas and in procurement departments for many years, yet companies found themselves unprepared for the pandemic-driven increase in supplier risks and the resulting supply chain disruptions.

As suppliers shut down across China and other global locations, it became increasingly more difficult—or impossible—to keep inbound products and parts flowing. As a result, many suppliers went bankrupt, or couldn’t maintain deliveries.

Rosemary Coates, Reshoring Insitute

Rosemary Coates is founder and executive director of the Reshoring Institute, a nonprofit organization focused on expanding U.S. manufacturing supply chains. She is also president of Blue Silk Consulting, a supply-chain management consulting firm that has helped global supply chain clients for more than 25 years. She is a best-selling author of five supply chain books, including The Reshoring Guidebook and the Legal Blacksmith – How to Avoid and Defend Supply Chain Disputes. She also works as an Expert Witness on legal cases involving global supply chains.

Rosemary serves on the board of directors at the University of San Diego Supply Chain Management Institute and teaches Global Supply Chain Strategy at UC Berkeley. She earned an MBA from the University of San Diego and a bachelor’s degree in business logistics from Arizona State University.

More counterfeits in your supply chain?

You do best to assume so, and that requires constant vigilance. Here are some tips.

The global counterfeiting problem is a multi-headed monster that continues to grow.

We heard about counterfeit PPE products that seemed to be everywhere during the pandemic, putting the lives of health care workers in danger. Demand was so high for these products that counterfeiters came out in full force to take advantage of demand volumes and high profits. Meanwhile, counterfeits of industrial and consumer products never slowed. Counterfeiters targeted industrial products, electronics, aerospace, metals, and other industries because shortages and disruptions in deliveries created opportunities.

Reshoring, Supply Chain Disruption, Survival Strategies – A Chat With Rosemary Coates

China’s zero Covid policy, and the shutdown of Shanghai are impacting global supply chains. To discuss this, and strategies organizations can take, I invited the Reshoring Institute’s Rosemary Coates back onto the podcast.

Time to celebrate women in supply chain

Recognize the growth of women in supply chain, and the potential for even more high-profile roles on this International Women’s Day.

International Women’s Day (IWD) is celebrated around the world on March 8. IWD’s purpose is to commemorate the cultural, political, and socioeconomic achievements of women. The day’s themes spotlight the women’s rights movement, gender equality, reproductive rights, and violence and abuse against women.

Against that backdrop, a Gartner survey says that women now make up 41% of the supply chain workforce. They are taking a greater share of top corporate supply chain roles with retail and consumer goods businesses showing the strongest leadership profiles.

Photo by Greg Rosenke on Unsplash

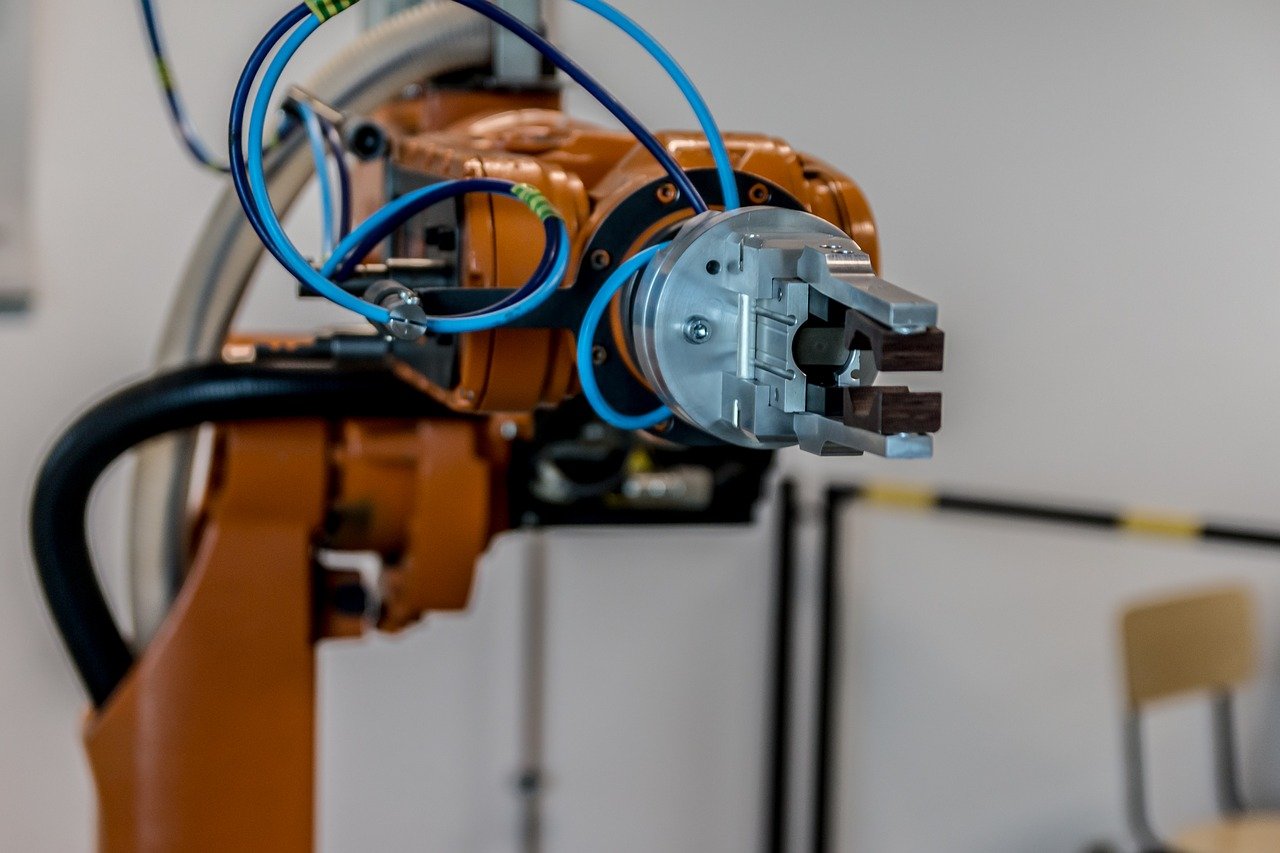

The Move Towards Automation Is Critical – conversation with Rosemary Coates

“To make your manufacturing lines more efficient and to extract labor, you have to move towards an automated solution. This makes manufacturing competitive in high-cost areas like America. It is one of the critical underpinnings of reshoring and looking at where in the world you should be manufacturing.” – Rosemary Coates, founder and Executive Director of the Reshoring Institute in a conversation with Lénárd Sándor.

Are there Uyghurs in Your Supply Chain?

Some companies unknowingly include forced-labor component parts from tier two or tier three suppliers. Are there forced-labor parts in your products?

Muslim Uyghurs, held in forced labor camps in China, have become front-page news. More recently, reports from human rights organizations reveal that many top American brands are using these labor camps as factories.

Global Supply Chains and Pandemic Prices

Hiccups in the global supply chains during the pandemic drove prices to record highs. In May this year, the U.S. consumer Price Index rose 5%, a 13-year record high. Mostly driven (one-third) by the price of used cars that rose 30%. New car sales rose past a record 7 million vehicles as dealer inventory fell to historical lows, while automotive manufacturers closed plants. The biggest reason: shortage of computer chips from contract manufacturers (foundries) in Asia. Experts predict high car prices will continue until 2023.

Both the problems and possible solutions are global and complex.

Come learn from expert and best-selling author Rosemary Coates, and ask your questions directly.

Bringing Manufacturing back to America

On this week’s Industrial Talk Podcast we’re talking to Rosemary Coates, Executive Director of the Reshoring Institute about “Bringing Manufacturing back to America”. Get the answers to your “Reshoring” questions along with Rosemary’s unique insight on the “How” on this Industrial Talk interview!

What Seems Impossible, Is Merely Difficult

The US has been the innovator of most breakthrough technologies and processes developed since World War II. With our constant emphasis on generating products that are newer, better, and faster, these innovations have set America apart from other nations.

Reshoring is Booming – Some Astonishing Statistics to Ponder

The pandemic is the primary reason for this uptick in the return of American sourcing and manufacturing.

Reshoring manufacturing is booming – but reshoring cannot simply be defined as reestablishing new factories in the U.S. that were once in China.

Who Owns Those Factories at the US-Mexico Border? Surprise! It’s probably the Chinese

Chinese factory development and investment on the Mexican side of the border has resulted in job creation in Mexico, but also in the U.S. through logistics operations and support services.

Who are the winners in manufacturing’s great digital race?

Many manufacturers are keen to embrace digital transformation, but which technologies should they invest in and which countries are winning the ‘digital race’?

Supply Chain Chat: Accelerating Trends Towards Reshoring and Why It Matters

In 2020, vulnerabilities and risks were exposed in offshoring manufacturing and supply chains. Companies were forced to find alternative ways to meet demand and the trend towards reshoring was accelerated. Watch this recording to hear from Stephanie Richelieu Stagger, COO/CRO at 3G, and special guest, Rosemary Coates, Founder and Executive Director of the Reshoring Institute, for a discussion about the accelerating trend towards reshoring and why it matters.

Discover How the Trend of Reshoring Is Impacting the Transportation Industry

The past 16 months have not been kind to supply chain professionals. From the pandemic to weather emergencies to port slowdowns to—of all things—a 1,300-foot container ship blocking one of the world’s busiest trade routes, the far-flung, highly complex supply chain networks feeding the global economy appear to have finally reached their limits.

Are There Counterfeits In Your Supply Chain?

In 2020, counterfeits were estimated at $1.8 trillion or 6.8 percent of global trade. Did you know that one out of 20 parts imported into the U.S. is counterfeit? In this APQC webinar, get insights into how to combat counterfeits in your supply chain with advice from Rosemary Coates, global supply chain consultant and an expert witness for legal cases involving counterfeit imports.

POLITICO – April 29, 2021 – commentary

‘Buy American’ sounds good in theory. Biden will find it’s painfully slow in practice.

The government’s ability to control the supply chains of private companies is limited, despite the administration’s pledge to aggressively enforce “Buy American” mandates.

Jaw-dropping, Spectacular Supply Chain Management

I am so impressed. I just got my second Covid vaccine. I scheduled both the first and second appointments online with no wait and at the appointed time I drove to the nearby vaccination location in Silicon Valley. There was no line. I filled out a form, showed my insurance card, and was escorted to a vaccination station, got my shot, waited 15 minutes, posted a photo on Facebook, and left. The whole process took less than a half-hour. It was very well organized, and stress-free. I am seeing postings from my friends all across the country who had similar experiences.

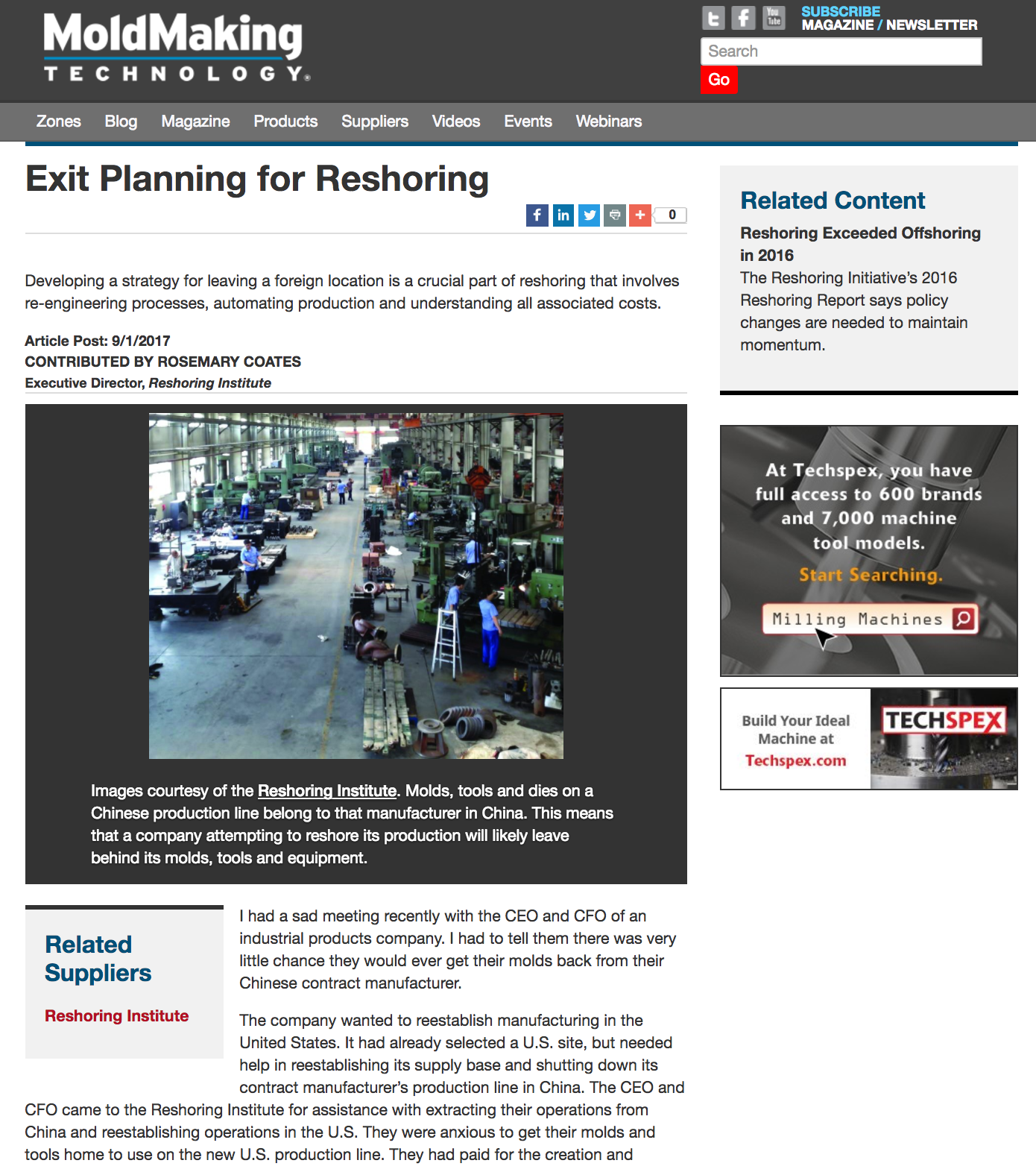

Challenges of Moving Manufacturing Out of China

When moving manufacturing out of China, there’s a lot to consider, e.g., employment contracts, retrieval of tooling and molds, IP protection, and taxes and fees.

There is plenty of manufacturing capability around the world for consumer goods, PPE, testing equipment, medical devices, consumer goods, and other industrial products. So why are companies reshoring their manufacturing operations now?

Photo by Gayatri Malhotra on Unsplash

Biden Has a Plan for Supply Chains and U.S. Manufacturing – But Will It Work?

Like all politicians’ statements, this one is high-level, sweeping verbiage with little or no defined detail.

The Biden-Harris transition website posts Biden’s policy for U.S. manufacturing and for addressing supply chain shortages due to Covid19. But can we take what is written at face value? Like all politicians’ statements, this one is high-level, sweeping verbiage with little or no defined detail.

Read More >

How to Create a More Resilient Supply Chain

Supply chain management veteran, Rosemary Coates, shares the ingredients for a more resilient supply chain and the lessons learned from COVID-19.

A Fresh Look at Reshoring

Running the gauntlet of COVID-19 has shifted how businesses think about global supply chains. Companies are not just looking at manufacturing costs, but at what happens if their supply chain shuts down.

Read More >

Eye On Industry – Episode 10: Made in America – Reshoring: Moving Production From China Back to the US

We’ve sat down with Rosemary Coates, Executive Director of the Reshoring Institute and President of Blue Silk Consulting. She is a management consultant with over 25 years of experience and 80 global supply chain clients and is also a Chinese Manufacturing Expert Witness for legal cases involving global supply chain matters. Rosemary is passionate about bringing manufacturing back to America.

“Watch: Is the Pandemic Driving Manufacturers Back to the US?”

Rosemary Coates, executive director of The Reshoring Institute, explains why the coronavirus pandemic might finally be the crisis that drives manufacturers to shift production from China back to the U.S.

Coates: COVID has led manufacturers in China to look at TX-MX border region

BROWNSVILLE, Texas – An expert on reshoring says the Texas-Mexico border region can benefit from the COVID-19 induced disruption to the supply chains used by manufacturers in China.

Rosemary Coates used to help U.S. companies locate in China. Now, as founder and executive director of the Reshoring Institute, a 501c3 nonprofit, and president of Blue Silk Consulting, she is doing the reverse.

Coates spoke at a Virtual Site Selector Tour of Brownsville hosted recently by the Greater Brownsville Incentives Corporation and Select USA.

Webinar: Diversify Your Global Supply Chain

Gain new perspectives on reshoring and expanding sourcing operations. Join DiCentral and special guest speaker, Rosemary Coates, Executive Director of the Reshoring Institute, on an exclusive webinar on diversifying your supply chain. Rosemary will share best practices on tariff strategies, supply chain relocation and leveraging new technologies to help your company rebound and rebuild post-pandemic.

Why Reshoring Is Picking Up

Has the Trump presidency brought back jobs to the United States from overseas? It’s a core question for voters this November.

Our Jessica Stone speaks with the Reshoring Institute’s Executive Director, Rosemary Coates, for answers.

77 | Internships, Manufacturing, & The Future of Work | with Rosemary Coates & Ryan Edwards

When the PAST Foundation travels around the country to talk to policymakers, colleges, universities, and trade schools, there’s one topic that gets brought up in just about every conversation: manufacturing. So it’s clear there’s a bigger conversation we really need to have around STEM education and the future of manufacturing jobs.

Americans Say They Prefer Products Made In USA and Will Pay More For Them

THE RESULTS ARE IN – Americans say they prefer products that are Made in the USA and they are willing to pay up to 20% more for them.

The Reshoring Institute recently surveyed nearly 500 Americans across the country and asked if they prefer to buy products that are labeled “Made in USA.” Would they be willing to pay more for these items? Nearly 70% of the respondents said they prefer American-made products. Slightly more than 83% said they would pay up to 20% more for products made domestically.

Decoupling & Reshoring

What is the current status of a “#decoupling” process? Is change happening now, in 6 months, or part of a much longer-term plan?

Are some industries going to #restore faster than others? which ones?

#Reshoring in the age of coronavirus: what are some of the #hurdles in #leaving #China?

In-Depth: The Case for a U.S. Industrial Policy

Listen to Rosemary Coates’ interview with Jessica Stone of Stansberry Insider Weekly. Starting at 6:58:00, she discusses the need for a U.S. Industrial Policy now. The Corona pandemic has exposed the dependence of America on foreign manufacturing, especially pharmaceuticals made in China. It is important for America to develop an industrial policy that supports critical and strategic industries.

America Doesn’t Have an Industrial Policy

Americans’ health and safety are at stake and now is the time to consider a national industrial policy to support the needs of our citizens.

China has the “Made in China 2025” industrial policy aimed at supporting the development of advanced manufacturing technologies. Germany’s industrial policy aims for comparative advantage in the production of high-quality, internationally competitive manufactured goods. Japan’s industrial policy was devised after WWII to promote industrial development by cooperating closely with private firms. Mexico’s industrial policy objective is to liberalize the industrial sector to increase industrial productivity and competitiveness.

Reshoring: The Hottest Trend in Business

Reshoring is the practice of transferring a business operation that was moved overseas — typically to a low-cost manufacturing — back to the country from which it was originally relocated. The goal of reshoring is to rebalance a country’s economy, create new jobs and cut its trade deficit.

Due to COVID-19, trade wars and tax cuts, businesses are now rethinking their global manufacturing and sourcing strategies. But it’s not as easy as it seems. Reshoring is complicated and can be costly. Leaving overseas operations can involve required pay-outs to employees, regulatory requirements and write-off of tools and machinery. Returning to your home country may be tough, too. You may have to develop a whole new supply base and deal with environmental, health and safety restrictions that are unexpected.

What Will Happen to Hong Kong?

President Trump has announced that the new Chinese national security law will require the United States to remove Hong Kong’s special economic status granted under American law.

Hong Kong has always been one of my favorite cities on earth, with its wonderful airport, gorgeous views of Victoria Harbor, the Star Ferry to Kowloon, and the bustling business environment. The energy level in the city is truly remarkable.

If you are doing business in Asia, you are probably using Hong Kong as the airport to make flight connections, manage cargo consolidations, an efficient seaport, and for global financial operations. Since WWII, Hong Kong has been an established city for international business and financial headquarters.

Reshoring in the age of coronavirus: beware of the hurdles in leaving China

Companies cannot expect to simply pack up shop, lock the doors, turn out the lights, and move back home, writes Rosemary Coates

We are in a global crisis. It’s a matter of life and death. There are still shortages of supplies and equipment around the world including acute shortages in America. We know there is plenty of manufacturing capability around the world for consumer goods, PPE, testing equipment, and medical devices such as ventilators. But flexing global supply chains is complicated and medical equipment is highly regulated by all governments. The results of inflexible global supply chains are overages of some supplies in some areas and shortages in others.

COVID-19’s Impact on Reshoring and the Supply Chain

The trade war and disruption from the coronavirus are spurring companies to rethink their global supply chains, manufacturing processes, factory design, automation and workforce needs. In this episode, Alan Rooks, Editor in Chief of Manufacturing Engineering magazine, talks with Rosemary Coates, Executive Director of the Reshoring Institute, about how the trade war and COVID-19 have affected manufacturers worldwide, why it has more companies considering returning their manufacturing to the U.S., the hurdles and issues to leaving China, and what decision-makers should be thinking about when planning for manufacturing in the future.

Business Facilities Webinar: Rethinking the Global Supply Chain

Rosemary Coates, Executive Director of the Reshoring Institute and the best-selling author of five books on supply chain management, discusses the impact of the COVID-19 pandemic on the global supply chain, and share how these disruptions may accelerate a ‘local for local’ strategy resulting in more reshoring of manufacturing.

Manufacturing Tomorrow

Listen to the podcast online at OSU.edu >>

Global Supply Chains In The Wake Of COVID-19 In Socially Critical Industries – Is It Time To Reshore?

As countries, economies, and businesses adjust to life in the COVID-19 era, many governments have started to ask questions about the wisdom and longer term implications of allowing key components of socially or economically critical products like pharmaceuticals, medical devices, and defense products to be sourced beyond domestic borders.

Read more at National Law Review >>

For Global Supply Chains the Worst Is Yet to Come

Many companies, especially small and medium-sized businesses do not have well-developed alternate suppliers outside of China, and finding new suppliers, qualifying them, and scheduling production is no easy task.

Read more at Supply Chain Management Review >>

Coronavirus and Your Global Supply Chain – Part 2 – Rising Panic

We have been helping companies with their global tariff strategies because of the trade war and the resultant economic emergency. The Coronavirus is causing a different kind of economic crisis that is even more urgent.

Read more at Supply Chain Management Review >>

A look at the Coronavirus and your global supply chain

Propelled by the Trump Administration Trade Wars, many companies have already left China for other Asian manufacturing locations. But – there are no guarantees that the virus won’t spread to these new locations.

Read more at Logistics Management >>

Supply Chain Turbulence in the Trade Wars

Rosemary Coates is Executive Director of the Reshoring Institute, President of Blue SIlk Consulting and an Amazon.com best selling author well known for her knowledge in the supply chain arena. She joins hosts Lew Weiss and Tim Grady to discuss the trade wars and its impact on businesses across America.

Listen on Manufacturing Talk Radio >>

Is it Time to Bring Manufacturing Back to the U.S.?

January 2019 – IHA got acquainted with reshoring advocate Rosemary Coates, who will explain the latest in tariff policies that can move a company to bring production back to the U.S. in her presentation at the 2019 International Home + Housewares Show. At the Show, the Innovation Theater will feature 21 presentations over four days. Topics will include design innovation, smart home, digital commerce and global market trends.

4 Considerations for Western Companies That Want to Leave China

January 2019 – Are you planning to leave China? With nearly 6,000 Harmonized Tariff Schedule item classifications identified for the imposition of a 10% to 25% penalty tariff on imports from China, it is time to consider all your options. The future of new tariffs and penalties is uncertain.

Rosemary Coates covers US Manufacturing

November 2018 – Join host Penny Rosema as talks with Global Supply Chain Consultant, Rosemary Coates as they cover the topic of US manufacturing and reshoring. Rosemary is the Executive Director and Chairman of the Board at Reshoring Institute.

What we talk about when we talk about manufacturing: FABTECH panel

November 2018 – American manufacturing is back—big time. Automation, the supply chain revolution, and a C-suite refocus on long-term planning bode well for this industrial renaissance, a panel at FABTECH explained here this week. But trade wars and a shortage of workers will likely lead to inflation and a recession—a downturn that might only be an economic hiccup, or might not.

What Is Your Import Tariff Strategy?

September 2018 – Are you leaving important tariff response strategy up to your import operations staff? It’s time for executives to lead. Nearly 6,000 Harmonized Tariff Schedule (HTS) item classifications have been identified for a 25% penalty tariff on imports from China. Even though some products have escaped the penalties so far, the future of new tariff classifications is uncertain. Will your products be next? What is your strategic response to new penalty tariffs?

What’s Your Apparel and Footwear Tariff Strategy?

By Rosemary Coates, Reshoring Institute – 09/11/2018

What should your company be doing to avoid or mitigate penalty import tariffs? Nearly 6,000 Harmonized Tariff Schedule (HTS) item classifications have been identified for the imposition of a 25 percent penalty tariff on imports from China. Even though many apparel and footwear classifications have escaped the penalties so far, the future of new tariff classifications is uncertain. Recently targeted products include sporting goods and some apparel items. Will your products be next?

Exit Planning for Reshoring

September 2017 – Developing a strategy for leaving a foreign location is a crucial part of reshoring that involves re-engineering processes, automating production and understanding all associated costs.

‘Offshoring’ expert says ‘reshoring’ vital to saving middle class

December 2016 – A push is underway in the Rio Grande Valley to promote Bi-National Economic Development, or BiNED, which aims to develop advanced manufacturing — and the high-paying jobs it brings — on both sides of the border.

Manufacturing is Leaving China – but is it Coming to the U.S.?

June 2016 – The reshoring phenomenon is real. It’s driven by rising labor costs in China, and the increasing risk of maintaining long supply lines for western markets. What can companies do to bring that production back to the U.S.?

Reshoring could spur demand for trucking

March 25, 2016 – A growing movement to bring so-called “advanced manufacturing” back to the U.S. – a strategic effort dubbed “reshoring” or sometimes “nearshoring” – could significantly ramp up truck capacity demand as well, according to two experts.

How to Avoid – and Defend – Supply-Chain Disputes

SupplyChainBrain.com

Disputes with suppliers can be costly. Now there’s a guide to avoiding them – and defending against them when they do occur.

Lessons in reshoring: How to Move Production Out of China

China Tariffs: The reshoring of manufacturing from China is no longer in question. Whether that work ever makes it back to the U.S., however, is another matter entirely.

Reshoring; Setting a Course on Manufacturing’s Road Home

From the giants of industry to SMEs spurring innovation and driving competition, manufacturers know returning operations to US shores from overseas factories will revitalize our economy. But exactly how does an enterprise of any size plan and execute their return?

Lessons in reshoring: The turnaround at GE’s Appliance Park

December 30, 2015 -Bright light reflects off the shiny exterior of row upon row of water heaters that stand like sentinels in Building 2 of General Electric Co.’s Appliance Park. The products soon will be shipped to retail stores such as Lowe’s, where they sell for about $1,000. The ordinary household product is part of an extraordinary turnaround story at one of Louisville’s largest employers and reflects the growing trend of reshoring: After decades of moving jobs to low-wage countries, American manufacturers are moving some jobs back to the U.S.

Reshoring, Bringing Manufacturing Jobs Back to U.S.

December 9, 2015 – Many American companies that have taken their manufacturing jobs overseas in favor of cost-saving affordable Chinese labor have either begun to bring some of those jobs back to the United States, or are seriously thinking about doing so, according to a consultant to the supply chain industry and director of the Reshoring Institute.

60 seconds with Rosemary Coates, Reshoring Institute and the University of San Diego

December 1, 2015 – At the Supply Chain Outlook Summit, you talked about your roles as a consultant, advising clients on their outsourcing strategies and also as the executive director of the Reshoring Institute, advising companies on how to bring some of that manufacturing back to North America and the United States. In a sense, you’ve seen them going and coming. How do you describe what is going on in the market today?….

For businesses in China, breaking up is hard to do

August 21, 2015 – The hottest trend in U.S. manufacturing is reshoring, and this means big opportunities for plastics manufacturers. According to a recent study by Boston Consulting Group, 54% of all U.S. companies with more than $1 billion in revenues are planning or considering reshoring at least some of their manufacturing. Wal-Mart’s U.S. manufacturing initiative promises to buy $250 million in U.S.-made consumer goods over 10 years. All of this reshoring will drive the need for plastic parts and products.

Skillfully Managing a Manufacturing Reshoring Project

December 23, 2014 – There’s more involved in successfully reshoring a foreign manufacturing operation back to the U.S. than simple cost comparisons. These initiatives have many moving parts and require careful planning. So where should a company begin?

What Happens When You Decide to Leave China?

December 8, 2014 – Reshoring is the hottest trend in U.S. manufacturing. According to a recent study by Boston Consulting Group, 54 percent of all United States companies over $1 billion in revenues are planning or considering bringing at least some of their manufacturing back to the U.S.

FAILURE ALERT: What Happens When Reshoring Goes Wrong

November 26, 2014 – A million things can go wrong every day in business. So when companies consider a new, big project like Reshoring they need to be especially vigilant and prepared. We want to see manufacturing come back to America to rebuild our middle class and strengthen our economy. But it’s not as simple as shuttering the production plant in China and recreating it at home. Reshoring is a complicated project with lots of moving parts and potential points of failure.

How to Ensure Your Reshoring Project Won’t Fail

June 12, 2014 – Consider Otis Elevator. OE is one of many U.S. manufacturers, including GE, Whirlpool and NCR, which announced they were bringing factories back to the U.S. from China, Mexico and other countries and whose efforts did not go well.

How Will You Know When to Reshore? Five Factors to Consider

February 27, 2014 – There are many factors to consider when “rebalancing your manufacturing,” reshoring some operations to the U .S. and leaving others in place to serve the growing Asian market. Several of the important factors in the original offshoring decisions have dramatically changed.

How To Avoid a Failed Reshoring Project

June 09, 2014 – Rising costs in China and shifting global economic forces are pressuring companies to reevaluate their global manufacturing strategies and consider localizing their operations. We’ve all heard the latest buzzwords: “reshoring,” “onshoring,” nearshoring and others. Some companies have started the process and have reported success. But many other companies are struggling with the reshoring.

How Will You Know When to Reshore? Five Factors to Consider

February 27, 2014 – There are many factors to consider when “rebalancing your manufacturing,” reshoring some operations to the U .S. and leaving others in place to serve the growing Asian market. Several of the important factors in the original offshoring decisions have dramatically changed.

Will You Know When to Leave China?

November 1, 2013 – Considered the “workshop of the world,” China is losing some of its cache’ as an unstoppable manufacturing powerhouse. Rising labor and energy costs are forcing manufacturers just like you to reconsider locating operations to even lower cost labor countries such as Vietnam and Indonesia.