5 Benefits of Reshoring by Rebecca Kennedy

5 Reshoring Benefits

5 Reshoring Benefits

In recent years, there has been a strong push from both American consumers and American businesses to bring manufacturing back home to the U.S.

This growing interest in “reshoring” isn’t surprising: Following the offshoring movement (the process of sending jobs from the U.S. to foreign countries with cheaper labor) that began in the 70’s and 80’s, the American economy has experienced its fair share of downturns and setbacks, including increased unemployment and weakened global competitiveness.

Check out these 5 undeniable benefits of manufacturing reshoring that can’t afford to be ignored.

1. Reshoring means higher quality products for consumers.

Foreign manufacturing is all about offering the cheapest solutions on the market – cheap labor, cheap tools, cheap technologies, and cheap processes.

Cheap manufacturing was all the rage several decades ago, but American consumers have begun to grow tired of poorly made (and sometimes even unsafe) goods produced in countries with lax manufacturing laws.

Today’s consumers having a growing interest in quality and value – areas where American-made goods rank at the top of the pack.

2. Reshoring helps keep the U.S. innovative & competitive.

Due to the previous shift towards overseas manufacturing, the U.S. has fallen off the bandwagon in terms of innovation and creating breakthrough technologies and solutions through research and development.

Countries that are heavy in manufacturing like Singapore, China, Korea and Japan have pushed their way to the top, in terms of global competitiveness through manufacturing innovation. (READ more about China Tariffs)

By bringing manufacturing back to the U.S., more and more U.S. companies will feel pressure to invest in R&D and get back in the global innovation game.

3. Reshoring allows for greater control of production processes.

Outsourcing products to overseas manufacturing plants means putting your full trust in their ability to manufacture products that meet your standards.

Outsourcing products to overseas manufacturing plants means putting your full trust in their ability to manufacture products that meet your standards.

However, many foreign nations have significantly less rigid laws in place for product standardization and quality assurance, safe and fair working conditions, and environmental protection. By bringing manufacturing back to U.S. soil, we can regain control of our production processes in all of these areas.

4. Reshoring means more streamlined distribution of goods.

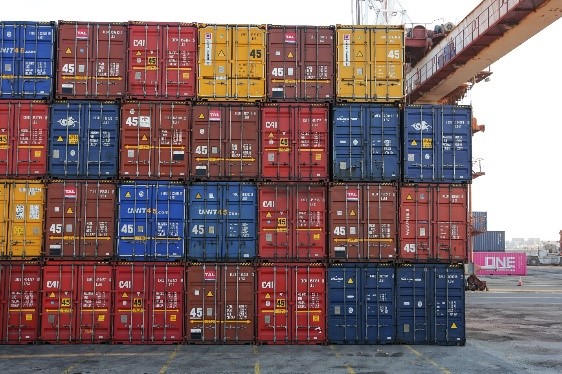

When goods are produced overseas, they must be shipped across the ocean to the U.S., where they are then delivered to warehouses, stores, businesses, and individuals. Naturally, this process of transportation and delivery is pricey, lengthy, and risky.

American-made goods have much simpler distribution processes and don’t require expensive overseas shipping, which also means less risk of damage, loss, and delays.

5. Reshoring brings American jobs back home.

Although the U.S. unemployment rate is nowhere near as high as it was during the recession, millions of American workers are still struggling to secure jobs.

Although the U.S. unemployment rate is nowhere near as high as it was during the recession, millions of American workers are still struggling to secure jobs.

Reshoring is one of the best ways to help provide valuable jobs for skilled U.S. workers, which means great things for the U.S. economy as a whole.

This week’s guest blog is from Rebecca Kennedy from https://www.omega1.com. OmegaOne started as a domestic manufacturer of stainless steel hydraulic fittings. Through the globalization of manufacturing, the company remained focused on domestic manufacturing while others sourced product overseas. The company has remained competitive focusing on specific markets that are not as price sensitive and where domestic product is preferred. Low cost product from foreign (primarily Asian) have driven prices down making for a much more price sensitive and commoditized market place. The strength of OmegaOne is product quality, competitive (domestic) pricing, responsive manufacturing, diverse inventory of hard to find items and responsive sales and customer service.

OmegaOne is proud to be an American-based manufacturer and supporter of American jobs.

Are you ready to reshore now? The Reshoring Institute offers low-cost professional consulting services for the following:

- Global manufacturing strategies

- Made in USA labeling requirements

- Reshoring Project Management

- Benchmarking

- Import tariff strategies

- Total cost of ownership modeling

- Technology evaluations

- Leaving your foreign manufacturing site

Based on your specific needs, we can design a custom project to support your reshoring efforts. Tell us what you have in mind and we will design a reshoring process and solution. Contact Us: Info@ReshoringInstitute.org or Call: +1 408-605-8867