Sourcing US Parts Blog Series – Part 2 – Separating From China

With the announcement of the tariffs, many companies are starting to investigate moving manufacturing back to the U.S. to avoid the tariffs. This is a great idea in theory but as we have learned over the last couple of years this isn’t as easy as you would think. If you move a current product you could face many sourcing difficulties that you may not have expected. Here are a few things to consider when starting your reshoring project with a current product:

With the announcement of the tariffs, many companies are starting to investigate moving manufacturing back to the U.S. to avoid the tariffs. This is a great idea in theory but as we have learned over the last couple of years this isn’t as easy as you would think. If you move a current product you could face many sourcing difficulties that you may not have expected. Here are a few things to consider when starting your reshoring project with a current product:

- Molding and Tooling – Your Chinese manufacturer will not willingly hand over their tooling and molding. You will need to have these remade or purchased. During our recent consulting projects we have learned that new molds could cost as high as $15,000 – $20,000 or more if made in the U.S. vs. $1000 – $2000 in China. We recommend that you have new molds and tools made and shipped to the U.S.

- Design documentation – Unless you have kept all design documentation in English with American units of measure, you will need to request your documentation from the Chinese manufacturer, have them translated, and add missing information. Getting these documents can be very difficult. During our last project, we were unable to get all the types of documents we needed. American suppliers requested CAD drawings, Gerber files, complete BOM for assembled parts and part specifications. The few documents we did receive were missing critical information that would have saved the supplier time and resulted in more accurate quoting.

- Embedded software – Did you write the software for the controller or that other microchip on the board that controls the something or other? If not, you will need to recode the hardware. Your Chinese supplier owns that IP and code and is unlikely to share that information with you. Depending on the cost, you may want to continue to purchase this from the supplier while you create your own.

- Out of date technology – We found that many of the parts we tried to source were obsolete and not available in the U.S.

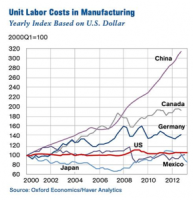

Manufacturing in the U.S. doesn’t mean you have to completely separate from your Chinese suppliers. Leaving China can be expensive and time-consuming. We recommend that you continue manufacturing Chinese/Asian products in China/Asia and move American products back to the U.S. In most cases, this will involve building a new, innovative, technically advanced manufacturing facility and automating your factory to reduce labor costs. In the long run, it may be more effective to develop a newer product to manufacture in the U.S.

The Reshoring Institute is here to help. Contact us for assistance on your reshoring project.